Key Bumping

Key bumping is a covert entry technique against pin-tumbler locks that uses a specially prepared key to "bump" top pins above the shear-line to allow the plug to rotate. There are two types of key bumping, pull-out and minimal movement, but both produce similar forensic evidence on the bump key and the lock.

Key bumping is similar in function to pick guns.

Key Bumping Principles

To bump a lock, a key is acquired that fits the keyway of the lock. The key is modified so that all cuts are at their lowest depths or lower. This is commonly referred to as a "999 key," because 9 is usually the designated lowest cut depth. If done by hand, a key gauge or micrometer can be used to measure the key and ensure cuts are deep enough. If done with a key machine, the key may be duplicated from a working bump key, or cut by code to the lowest depths.

In the pull-out method, the key is inserted into the lock fully then withdrawn one pin space. In the minimal movement method, the key is further modified by removing material from the tip and shoulder of the key. The minimal-movement key is inserted completely into the lock. In both cases, light tension is applied to the key and a tool (known as a bump hammer) is used to impact the bow of the key, causing the key to be forced into the lock. The impact on the key causes kinetic energy to travel from the key to the top pins, causing the top pins to momentarily jump. If all top pins jump above the shear-line while tension is applied the plug is free to rotate.

As with pick guns, the main source of forensic evidence of bumping is on the pins themselves. The action of striking the bump key into the lock causes distinct dents and scratches on the bottom pins. Bumping also affects the face of the plug, the keyway profile, pin chambers, top pins, and the bump key itself. For forensic examination of bump keys, see the Key Analysis page.

The pin chambers within the plug may also be damaged by bumping. When kinetic energy does not properly transfer to the top pin, the pin stack may instead press against the chamber walls (caused by the movement of the bump key). Repeated bumping may cause these areas to distort, stretching in various directions. |

|

One of the most noticeable pieces of evidence from key bumping is damage to the face of the lock. This is caused by the shoulder of the key impacting the area above and below the keyway. The use of modified shoulders may prevent this from happening, see the Anti-Forensics page. |

|

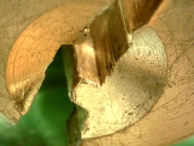

In the minimal-movement method, material is removed from the tip and shoulder. This makes the method work but also inserts the key far enough that in some cases affects the keyway. This is due to the key material getting thicker as it reaches the bow. In the photo, this can be seen around the edge of the keyway. |

|

coming soon: Effects of Wear

If you would like to help this site by donating any bumping tools, please contact me.